Frequency converters play extremely important functions in machine systems, especially in the automation industry. With the outstanding benefits it brings, frequency converters have become an indispensable part.

1. Change engine speed to meet process requirements

One of the important functions of the frequency converter is to change the motor speed to meet process requirements.

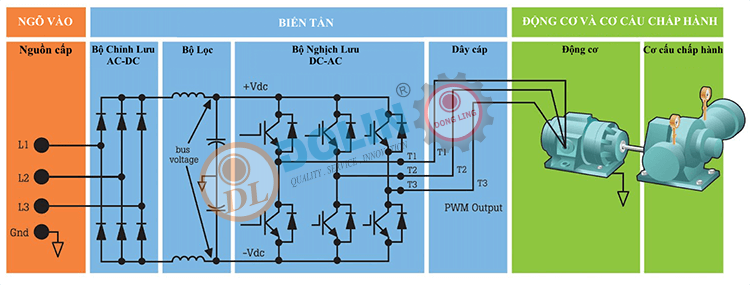

The working principle of the frequency converter is based on three main parts: rectifier, filter and frequency converter. There:

(1) Rectifier: Converts one-phase or three-phase alternating current into direct current (DC voltage) and stores it in a capacitor.

(2) Filter: used to filter out flat DC voltage.

(3) Frequency converter: Apply PWM pulse width modulation through IGBT (isolated gate bipolar transistor) system to generate symmetrical three-phase voltage.

(4) Engine speed calculation formula: N=(2x60xf)/P

F is the voltage frequency supplied to the motor

P is the number of motor pole pairs

According to its working principle, the frequency converter symmetrically adjusts the frequency of the three-phase output voltage to supply power to the motor, thereby adjusting the motor speed and meeting the process requirements.

The function of the frequency converter is to change the motor speed to meet process requirements

2. Protect the engine and reduce mechanical wear

Inverters play an important role in protecting motors and reducing mechanical wear. When the motor starts, the frequency converter changes the speed from starting to rated speed, causing the starting current to not exceed 1.5 times that of star-delta direct starting.

The frequency converter also integrates overload, overcurrent, high voltage and low voltage protection functions to increase the service life of the motor.

In addition, the frequency converter helps reduce mechanical wear by smoothly regulating the motor’s starting process and avoiding shocks.

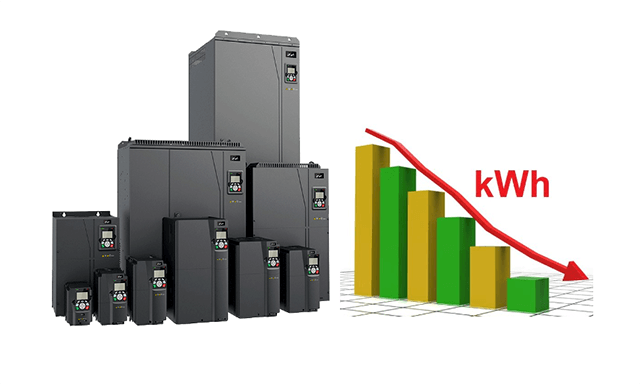

3. Energy saving

An important advantage of inverters is energy saving. Compared with direct start, the inverter starting current is reduced by 4-6 times, helping to reduce power consumption by 20-30%.

The inverter is also used to control flow and pressure and help reduce/stop the motor in idle mode, thus optimizing power usage.

逆變器的作用是節省能源消耗

4. Improve production efficiency and product quality

An inverter can help increase the speed of a motor so that it can run at a higher speed than if it were powered by direct power.

This is particularly useful in many industrial applications, such as textile, dyeing, printing, papermaking and woodworking, where high speed is an important requirement to increase production efficiency. The inverter enables the motor to run at optimal speed and maintain a high level of efficiency during operation

5. Control system operation through operating parameters

The frequency converter can provide monitoring parameters such as motor operating frequency, speed, voltage, and current.

These parameters help operators easily and quickly check engine health. If any problems arise with the engine, these parameters will provide the operator with appropriate adjustment and handling information, helping to achieve higher performance and avoid engine damage.